| Marquis_Rex |

Posted

Thursday, Jan 25th 1:49pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 510

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

Engines that have fast burn do not need a lot of ignition advance.

Factors that effect burn rate within the combustion chamber include charge motion, squish/stroke/mean piston speed (all inter related), the amount of Exhaust Gas residual within the cylinder and the farthest point the burnt charge has to reach from the spark plug (this is why central plugs are generally a good thing). The amount of Exhaust Gas residual left in the cylinder at full load high speeds are typically quite low anyway.

An optimally mapped engine will typically have an ignition value that gives the best torque- advancing the ignition any more will either LOSE torque or run the engine into knock. The former is known as MBT timing while the later is timed to DBL (detonation border limit- usually set a safe number of degrees away from detonation).

A compact combustion chamber (small included valve angle) with a low surface to volume ratio, not too large a bore, adequate charge motion and a centrally placed spark plug will have a rapid burn rate. Burn rate is usually measured in the industry via the convention, 10 to 90% burn but these kinds of numbers are usually difficult to come by. You need very expensive in cylinder pressure transducers and extensive data acquisition and logging systems.

There isnít a DIRECT correlation of the amount of ignition advance required and 10 to 90% burn rate (although after collating reams of data Iíve come up with some rules of thumb). In the absence of other data ignition advance values alone can be used as a rough indication of how fast the burn is.

Armed with this information- it throws me that the later E30 M20 BMW 2 valve small six has very low ignition values at high revs, as set from the factory. This is all the more odd, seeing as the later E30 M20s came with very low compression ratios so are unlikely to be retarded values for knock.

To give a feel for what values are more common:

A modern 3 litre 4 valve 240 Bhp 89mm bore V6 needed close to 30 degrees ignition at full load high speed.

A 4 valve 4 litre 290 Bhp V8 with 86mm bore needed close to around 26degrees at full load high speed.

The above V8 combustion chamber not only had a smaller bore but also a narrower valve angle- so this adds up.

BMW 328i M50 (single VANOS) needs about 22 degrees at full load high rpm.

The 231 Bhp 330i is very similarly timed to the 328i.

In addition to these Iíve looked at dozens of engines, including Honda S2000s, Alfas, Fords etc etc

Two valve engines probably provide a more valid comparison to the venerable M20- as they typically all have spark plugs offset from the central position. Iíve picked Hemi style engines- but nearly all of them have a much deeper/wider angle than our unusually shallow valve angled M20 (2 x 22 degrees)

Mercedes twin cam M110 (as used up the W123 280E)- requires about 35 degrees maximum advance

Jaguar old XK straight six- sources vary here- but Iíve seen up to 36 to 38 degrees needed for this very deep chamber.

Porsche 911 Single plug again around 32 to 36 degrees depending on variant

The E21 M20 variant is rated at 22 degrees at 1500 rpm, but itís maximum advance is about 28 degrees

When the E30 M20 323i engine was released in the early eighties- itís ignition values were much more retarded than the outgoing E21 variant- in addition it had an odd cantilever mechanical advance distributor- that advanced the ignition up to a point and then started to retard it. I can understand the need for more ignition advance at low to medium speeds than high speed- this is common with peakier engines- such as those without Variable cam timing- where the cylinder filling at low speeds isnít great. For instance, if you compare the optimised ignition advance curves of a conventional Jaguar V8 to a Aston Martin V8, youíll find the Aston needs more advance at low to mid range, because air flow has been biased toward top end. Well in the case of our Bimmers, they all produce peak torque at a highish 4000 rpm plus with no VCT.

So It reaches a maximum of 19 degrees at 3000 rpm and then retarded as far as 16 degrees at 5000 rpm- which is a really low value.

Itís unlikely to be very knock limited running a 9.8:1 compression ratio. I can understand why it would be retarded over the E21 variant perhaps because it breaths better. Better breathing engines is similar to running your engine at a higher load- so often need retarding of the ignition.

So it lead me to conclude that it was a limitation of the mechanical advance components. Until I obtained values for a late E30 M20 325i:

This engine is set from the factory to a maximum advance of just over 22 degrees at 3250 rpm and then, like its E30 323i predecessor, retards aggressively down to around the 12 degree mark at 5000 rpm. This is a very low number for full load high speed. At full load high speed, this engine wonít be producing the kind of breathing as a 4 valve, and yet it is set at a lower ign advance value. Also, recall that the late 325i E30 had a low 8.8:1 Compression ratio- so will hardly be knock limited.

I had originally thought that the M20 chamber was similar to other typical Hemis- of a slow burn due to lack of charge motion until I researched and found out about BMWs patented ďDrei-Kugel-WirbelĒ chamber: if you look at the valves of an M30 or M20- youíll find them slightly offet to the cylinder axis- this apparently induced motion.

This may explain why the engine will burn faster than Jaguar XK , Mercedes, Alfa and Porsche hemis, but not to the point where the E30 325i only needs 12 degrees ignition advance at full load/rpm. I do intend to flow test to verify if this arrangement actually gives any swirl motion within the chamber.

In my own car, IĎve fiddled a lot with the ignition and am running a maximum of around 34 degrees at 2000 rpm and then it gradually goes down to 30.5degrees at 4500 rpm Ėprobably continuing to get less and less.

My engine is a variant of a M20, a 2.7 litre with the big port 325i head, about 10.8:1CR, forged pistons, schrick 284 camshaft, tuned length headers. Running 95 octane fuel my car will experience light knock in summer conditions in 5th gear at 160 to 170 KM/H (above 100 mph). It will also exhibit a similar effect at in third gear at 75 mph- I intend to use my vehicle simulation package to determine exactly what engine load conditions these are.

With 98 octane any sign of knock goes away and in the cold winters there isnít any knock using 95 octane. Indications are that my ignition isnít far off optimum- however I still donít understand why the E30 325i et al from the factory were set so retarded.

|

|

|

| imaradiostar |

Posted

Friday, Jan 26th 6:49am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 989

Nashville, TN

81 323i, 82 525i, 85 524td, 90 535i |

I love it when you post stuff like this- next time you're in the states I've surely got to buy you a few beers and talk engines!

I have an idea about the ignition timing. My idea may show my lack of understanding but I'm willing to take that risk. Perhaps the M20B25 was built with the thought that in the life of the car there will be a substantial amount of carbon build up on the back of the valves, the intake runners and the tops of the pistons. The conservative timing at high rpm could compensate for the heat accumulated during extended high rpm running on an engine that's not breathing as well as it was and may have much higher compression as a result of buildup in the combustion chamber. It's a thought anyway. Could emissions have been a concern?

I suppose we could find a dyno facility that has some sort of steady-state dyno and mess with the timing until we find the "ideal" advance at any given rpm and load. Doesn't this vary hugely with setup though? Shouldn't my 731 head engine be wildly different from your 885 head engine, even though they share bottom end dimensions?

I'd like to hear your opinion on the differences between the m20b25 combustion chamber and the late m30b35 chamber as equipped on e32 and e34 cars. They're pretty similar in specific output- 67 hp/liter for the 2.5 and 64 for the m30. I feel as though there's plenty of room to improve both of them but I think it's interesting that BMW didn't choose to develop the "dish in dome" configuration for the late M30 even though they'd already done so and achieved higher specific output with the M20. Any idea why this is the case?

I ask the above for a specific reason- when I look at certain (domestic) engines from the Engine Master's Challenge that are making excellent power numbers, they tend toward flat topped pistons with huge squish areas and a piston dish that is similar in size (though shallower) and shape to the combustion chamber above it. This seems more similar to the flat chamber on the M30 (albeit the M30 had no dish by then). It's almost as if they're duplicating the pent roof design (somewhat pyramid shape chamber in the head) with a squish area at the extremities. Specifically I'm thinking of John Kaase and his 13:1 pump gas engine from a few years ago. It had amazing output numbers from idle to redline!

I don't know how much of a purist you are- how far are you willing to push it? Is loosing the dish-in dome a sacrilege? Would it even be worth it to ditch it in the name of simplifying the chamber and piston design requirements?

I picture (for an upcoming project) an M20B25 with the edges of the combustion chamber welded up a little bit to create a flat squish area. A piston with a similar squish area and a dish matching the combustion chamber would be used. The factory dish in dome becomes impractical with a huge bore and stroke number and I believe this is the next logical step toward building a very high power M20. In addition it serves to make the combustion chamber more compact. In the interests of centralizing the spark plug better an alloy plug could be welded into the spark plug hole and a smaller spark plug would be positioned closer to the center of the combustion chamber.

In the end this would allow a large squish area around the perimeter, a large enough bore to prevent the valves from being shrouded by the cylinder wall, and valve reliefs being unnecessary because of the dish in the piston matching the shape of the combustion chamber. The compact chamber should burn rather quickly and the swirl action created by the large squish areas should aid in detonation resistance. It would seem this combo (for large bore and stroke and reasonable compression ratio numbers) could yield a more compact chamber than would be available given the same bore and stroke (say 86mm x 89mm) with a dish-in-dome design.

Thoughts? I haven't built this idea yet, only toyed with it. I will build it one day but I haven't the money at the moment!

jamie |

|

|

| Marquis_Rex |

Posted

Friday, Jan 26th 11:08am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 511

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

I might take you up on that drink when Iím next there!

Interesting theory. I donít see why an E30 M20 would be prone to carbon build up more than an E21 unless it was something they discovered in the E21 series. What leads to excessive carbon build up? Usually excessive fueling perhaps oil burning, wrong grade of plug-perhaps leading to fouling.

Also if an engine doesnít breath as well at top end- it would typically need more ignition- hence why typically 2 valve engines usually need more ignition advance at top speeds than 4 valvers. Also, bear in the mind that the compression ratio in Europe of the 325i E30 started off at 9.7:1 and went to 9.4:1 and then finally settled to a very low 8.8:1. The M30 big six also had its compression ratio lowered also. This was at a time when the Pent Roof chambed M50 (introduced in the E34 in late eighties) had high compression ratios, as did the M42 and S14 which hints that knock systems were sufficiently developed detct and take action in the late eighties . The lack of top end ignition and lower compression ratios hints something more sinister about the burn of the Drei-Kugel-Wirbel hemis. Either they have a faster burn or if/when knock does occur- is it more destructive? For a while I did wonder whether it was due to the incompetence of BMW engineers (like the E21 front suspension) and they simply carried over a lot of similar ignition values to the motronic system from the L jetronic of the early 323i E30. However there were a few remaps of the E30 325i, usually going hand in hand with the different compression ratios and each subsequent remap exhibited the same low ignition phenomenon. If it was a ďboobooĒ I doubt theyíd carry it on.

I think the domed edges of the 325i M20 work well as they give squish (you donít neccessarily need flat squish) with minimal valve flow shrouding. Flat squish near valves can give shrouding- hindering low valve lift flow. I think the offset dish in dome- concentrated the combustion chamber around the spark plug- so was a good compromise toward a central plug (at TDC anyway), but more importantly allowed what was pretty much a small volume combustion chamber achieve a lower compression ratio (40 ccs is a lot smaller than the corresponding M30s etc etc). The bigger you go on the capacity, the more you need to get volume in the combustion chamber to bring the compression ratio down.

The problem with domes on pistons Ė domes at the centre of pistons anyway, or other such protrusions is that they impede the smooth progress of the expanding flame front- which is roughly spherically shaped. This will effect the 90 to 100% burn rate. Flat tops are ok, and I doubt youíd see much physical difference between a dish in dome and a flat topped dome if the compression ratio and the area of squish was kept constant. Combustion quality has a primary influence on part load fuel economy- air flow has a higher influence on power/torque.

The issue I would have with a more central spark plug is it will limit the use of bigger valves- which is imperative and far more important that combustion Ė for top end flow/power- especially when the capacity is increased. I think I may be able to squeeze a 45 or 46 mm inlet valve into the chamber and a slightly bigger exhaust valve- but they could contact one another at TDC if Iím not careful with my cam profiles and these valve sizes are already on the limit for good airflow for a 3 litre plus engine and I may need to compensate by going for longer durations.

I think the thing about squish on a shortish stroke engine such as the 325i E30 is that itís benefits mainly become visible at higher engine speeds- may be this is why the ignition amount at high revs is low in the M20? However it works far better with the longer strokes weíre talking about of the m20 ďstrokersĒ.

And finally I donít think the ignition characteristics of the 731 to the 885 chamber will be wildly different. The 320i/6 may need a bit more ignition advance because it has a poor surface to volume ratio and loses a lot of heat. Higher compression ratios will have a slight effect, but not by much- may be 2 or three degrees. A wilder cam will mean more ignition advance will be needed at lower speeds and less at top end but all other things being equal the ignition curves of the two cyl head types wonít be that different.

|

|

|

| TJ |

Posted

Friday, Jan 26th 11:25am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 19

NY, USA

82 528e2i 84 320i/4 80 320i |

Thanks for another informative thread. I spent some time trying to make sense of ignition maps in my 528e motronic that I use with my 2.7 w/ 885 head. One thing I have yet to do is hook up my timing light and figure out how the numbers in the EPROM translate into degrees of advance. Although, even then it'll be hard to predict by just looking at the EPROM what WOT timing will be, since I don't know what the measured load (AFM flap position) will be for each RPM range. There're only 7 RPM ranges so I think the advance (full load) stays the same from about 3500RPM on up.

I ordered a Megajolt kit (see http://picasso.org/mjlj/) that I intend to put in my 320i so I'll have a lot of tuning work to do on that. Any thoughts on what the M10 map should look like? Mine is an '81 1.8L stroked to 2.0l with domed 10:1 pistons. |

|

|

| Marquis_Rex |

Posted

Monday, Jan 29th 1:50pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 512

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

| TJ wrote: |

I ordered a Megajolt kit (see http://picasso.org/mjlj/) that I intend to put in my 320i so I'll have a lot of tuning work to do on that. Any thoughts on what the M10 map should look like? Mine is an '81 1.8L stroked to 2.0l with domed 10:1 pistons. |

TJ I'm not sure what your ignition values should be on your M10.

I would initially use the original distributor ignition values and then sweep from there on a dyno to try to realise benefits. Try to find the original values of ignition of the 2 LITRE M10- may be from a 2002 or early 320i. May be the European market values are more representative as the US cars were often retarded as a quick (and aweful) way to get through emissions. Sometimes these values are availiable in Autodata manuals at various rpms.

If you're using a wilder cam, you typically need more ignition advance at low speed (over baseline) and less at top end when the breathing has improved |

|

|

| TJ |

Posted

Saturday, Feb 3rd 10:29am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 21

NY, USA

82 528e2i 84 320i/4 80 320i |

off the topic of the M20 now, but FYI I found some numbers to start off with in the Haynes manual:

Bosch JFUD 4 (early Euro? 320i), vacuum disconnected

1000RPM 11-13

1500RPM 22-24

2000RPM 26-28

2500RPM 28-30

3000RPM 30-32

4000RPM 32-34

Bosch JGFU 4 (1.8L 320i), vacuum disconnected

1000RPM 10-16

1500RPM 14-22

2000RPM 20-28

2500RPM 26-34

3000RPM 32-39

4000RPM 32-38

|

|

|

| Marquis_Rex |

Posted

Sunday, Feb 4th 12:41pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 513

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

| TJ wrote: | off the topic of the M20 now, but FYI I found some numbers to start off with in the Haynes manual:

Bosch JFUD 4 (early Euro? 320i), vacuum disconnected

1000RPM 11-13

1500RPM 22-24

2000RPM 26-28

2500RPM 28-30

3000RPM 30-32

4000RPM 32-34

Bosch JGFU 4 (1.8L 320i), vacuum disconnected

1000RPM 10-16

1500RPM 14-22

2000RPM 20-28

2500RPM 26-34

3000RPM 32-39

4000RPM 32-38

|

With those ranges that you've quoted for the 2 litre 320i, I'd aim for the middle of those values. If you car has a wilder cam, then perhaps go for the lower of the range and high rpm and then the higher of the values at low rpm- as the breathing would be worse.

It's interesting to note that the 1.8 needs more ignition than the 2 litre. This is much like the Jaguar 3.2 V8 (euro only) vs the 4 litre, where the shorter stroke and worse surface-volume-ratio combustion chambers in general lead to greater heat loss- so more ignition is needed.

Both seem to need more ignition than the M20 chambers- even the earlier 1264200 cyl head M20s, again- the M20 having a more compact chamber in general- and more nearer the thermodynamically ideal "square" configuration.

Will be testing a 1264200 cylinder head on the flow rig next week- not only for outright flow but also for swirl and tumble motion. |

|

|

| imaradiostar |

Posted

Monday, Feb 5th 5:23am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 1002

Nashville, TN

81 323i, 82 525i, 85 524td, 90 535i |

How does the longer stroke in the average M20 stroker effect burn? (most of us are using 81, 84, 85.8 or even 89.6 mm stroke cranks.) I have two engines going to the machinist at the moment- one with an ETA crank and one with a b28 crank. I'm curious if the nearly square or even oversquare design of the stroker calls for a flatter advance curve.

How bad is it really for people to use flat topped (ETA) pistons with the 885 casting head? Is the mismatch of combustion chamber shapes really as bad an idea as it seems or am I putting too much emphasis on the importance of squish area? I ask because this seems to be a common thing people do to build a turbo engine. I have a set of M44 pistons that I'd like to use and I'm curious if the better flow of the 885 is worth it if I'm not taking advantage of the combustion chamber shape.

jamie |

|

|

| Marquis_Rex |

Posted

Tuesday, Feb 6th 9:24am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 515

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

| imaradiostar wrote: | | How does the longer stroke in the average M20 stroker effect burn? (most of us are using 81, 84, 85.8 or even 89.6 mm stroke cranks.) I have two engines going to the machinist at the moment- one with an ETA crank and one with a b28 crank. I'm curious if the nearly square or even oversquare design of the stroker calls for a flatter advance curve. |

All other things being equal if you increase the stroke and therefore increase the cylinder capacity without improving the ports/ammending the valve sizes or changing the cam timing, your volumetric efficiency at top end will drop off- in fact the whole engine VE curve with pivot and be biassed toward low speed. This will be like running at a slightly higher load at low speed and a lower load at higher rpm. Therefore there will be more ignition requirement at high speed and perhaps a bit less at low speed- especially if you were knock limited in the first place. I realise this information may seen to contradict the "shorter-stroke" poor surface to volume ratio- info I gave earlier- but in actual fact the advance requirement is effected by so many things and after a certain length of stroke for a certain size of chamber the S-V ratio is no longer a predominant issue

| imaradiostar wrote: | How bad is it really for people to use flat topped (ETA) pistons with the 885 casting head? Is the mismatch of combustion chamber shapes really as bad an idea as it seems or am I putting too much emphasis on the importance of squish area? I ask because this seems to be a common thing people do to build a turbo engine. I have a set of M44 pistons that I'd like to use and I'm curious if the better flow of the 885 is worth it if I'm not taking advantage of the combustion chamber shape.

jamie |

For a gasoline engine I think air flow is always primary. The main reason to focus on part load combustion is part load fuel economy and emissions- the faster burn is always nice tohave but not at the expense of good air flow- if it means compromising your ports or valves. This is why Formula 1 engines have such aweful looking combustion chambers |

|

|

| redmist |

Posted

Tuesday, Feb 6th 10:03pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 1028

NY USA

357i , 325i e30 turbo |

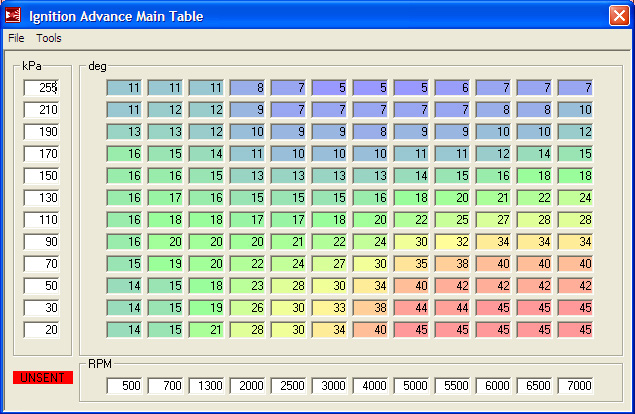

Here is a megasquirt timing map from a m20 with the following mods:

Engine & Modifications: M20 2.8 liter - 9:1 Ross pistons, MLS .83mm gasket, Metric Blue bolts

TurboCharger: Garrett TO4e .50a/r compressor .68a/r turbine

Wastegate: Turbonetics Deltagate 35mm with boost controller

Manifold: Proturbo.fi manifold adapter

Exhaust: 3" no cat, magnaflow straight through muffler

Charge Pipes: 2.5 inch mandrel bent

Intercooler: Starion 16.5x10x2.75"

Injectors: 80lb/hr

Fuel Type: 92 octane (pump)

Engine Managment: Megasquirt1 v3 board MSNS-extra 029q2

And here is one from a basically stock engine:

Stock m20b25, cat-less euro edition (9.7:1 compression) running megasquirt 2 ECU

Spark map is a fusion of stock dme173 map, JC chip map, other ms spark maps

The fuel is 98ron=90mon=93pon

|

|

|

| imaradiostar |

Posted

Wednesday, Feb 7th 4:30am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 1003

Nashville, TN

81 323i, 82 525i, 85 524td, 90 535i |

| Marquis_Rex wrote: | | For a gasoline engine I think air flow is always primary. The main reason to focus on part load combustion is part load fuel economy and emissions- the faster burn is always nice tohave but not at the expense of good air flow- if it means compromising your ports or valves. This is why Formula 1 engines have such aweful looking combustion chambers |

Makes sense. Let me ask a more specific question. Say we have equal (or very similar) flow from two different heads and combustion chambers shapes- both 2 valve/cyl designs. Assume we're using highish octane pump gas (92-93 US octane) and a reasonable camshaft for street use (solid lifter duration below 295, for example). One head will have an open "hemi" design with no squish areas and one will have valves canted ala BMW with squish areas on both sides of the valves like a Peugeot 505 head. The latter head will have significant squish area. Which is likely to be the better head?

I understand there are so many other factors at work in this but sure there must be some generalizations that can be applied to this scenario.

jamie |

|

|

| Marquis_Rex |

Posted

Thursday, Feb 8th 8:59am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 517

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

| imaradiostar wrote: | | Marquis_Rex wrote: | | For a gasoline engine I think air flow is always primary. The main reason to focus on part load combustion is part load fuel economy and emissions- the faster burn is always nice tohave but not at the expense of good air flow- if it means compromising your ports or valves. This is why Formula 1 engines have such aweful looking combustion chambers |

Makes sense. Let me ask a more specific question. Say we have equal (or very similar) flow from two different heads and combustion chambers shapes- both 2 valve/cyl designs. Assume we're using highish octane pump gas (92-93 US octane) and a reasonable camshaft for street use (solid lifter duration below 295, for example). One head will have an open "hemi" design with no squish areas and one will have valves canted ala BMW with squish areas on both sides of the valves like a Peugeot 505 head. The latter head will have significant squish area. Which is likely to be the better head?

I understand there are so many other factors at work in this but sure there must be some generalizations that can be applied to this scenario.

jamie |

Squish will give an improvement to the combustion process but this will barely be noticeable in terms of full load performance. Perhaps less than 1 to 2 %. This is backed up by test and simulation. More significant will be it's effect on the ability for the engine to run lean or on the engine to be tolerant to running heavily retarded without misfire for fast catalyst warm up.

Anyway, after the tests I've just done I'm knocked out by te amount of motion the M20 "200" cylinder head generates. It generates alot of Swirl AND Tumble-and it is usually very rare to get tumble motion on a 2 valve. I've seen less tumble motion in a 4 valve pent roof!

Charge motion is more important than Squish- but even this won't have a massive effect on power output. The improvements in the burn process will perhaps give you a benefit of 2 % at best.

The kind of traditional flat squish that hits port flow coefficients by shoruding the valves will certainly hit power by a massive percentage. We tried this on a Jag V8. Much beter to use the angled/faired in squish of the 325i/885 cylinder head casting- which doesn't compromise the port flows that much. Typical BMW- striving to get the best of both worlds.

The BMW style of induced swirl charge motion seems to leave the port flows coeffcients intact though also.

If an area could be focused on for M20 development- it would be trying to fit a second plug and raising the compression ratio correspondingly. I posted his idea another board- already voicing the issues of what to do with the water jacket- only to get a predicatable know-it-all response from our hatted mental internet-guru friend down under

So if you, or anyone else who's open minded can think of a way of fitting another plug....

Redmist thanks for the values. What KPa/manifold pressure value coresponds to full load? 200 and something off KPa seems quite a low pressure for WOT?

|

|

|

| redmist |

Posted

Thursday, Feb 8th 7:05pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 1029

NY USA

357i , 325i e30 turbo |

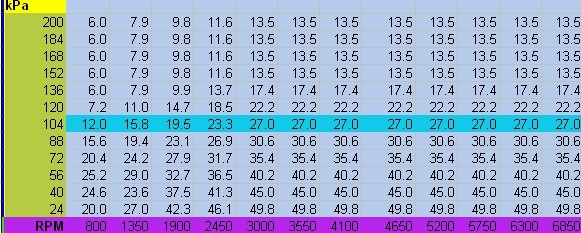

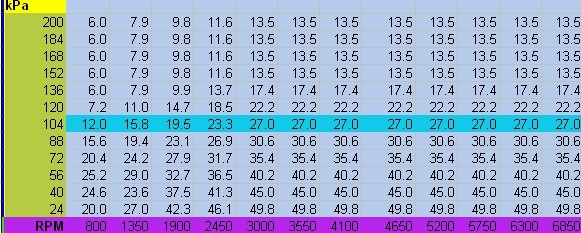

Marquis 100Kpa is full load NA. Here is something else interesting on this topic I came across on doing the tables for my super-eta, "i" head/cammed turbo and nitrous motor.

"As a starting point older two valve motors (1960 to 1990) should have max advance of 36, newer two valve motors 30. Then subtract 3 degrees for bores less than 89mm. Subtract 2 degrees for regular fuel, 1 degree for mid-grade and 0 for premium. This gives you a maxiumum advance number. If you have a good squish and quench subtract another 2 degrees. This should fill the ignition table from 3000 to redline at full NA load, 100KPA. For idle to 3000 rpm the advance should proceed linearly from 8 dgrees for a stock engine, 16 degrees for a "hot" engine. Below 100KPA add 0.3 degrees per 1 KPA drop. For boosted engines you subtract 0.3 degree for every 1 KPA above 100."

This is a good baseline tune, you of course have to tweak these numbers for you particular engine, modifications and environment"

Follwing this this is what I come up with for a 15psi boosted m20 (rough map)

|

|

|

| Marquis_Rex |

Posted

Thursday, Feb 15th 11:23am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 520

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

| redmist wrote: | Marquis 100Kpa is full load NA. Here is something else interesting on this topic I came across on doing the tables for my super-eta, "i" head/cammed turbo and nitrous motor.

"As a starting point older two valve motors (1960 to 1990) should have max advance of 36, newer two valve motors 30. Then subtract 3 degrees for bores less than 89mm. Subtract 2 degrees for regular fuel, 1 degree for mid-grade and 0 for premium. This gives you a maxiumum advance number. If you have a good squish and quench subtract another 2 degrees. This should fill the ignition table from 3000 to redline at full NA load, 100KPA. For idle to 3000 rpm the advance should proceed linearly from 8 dgrees for a stock engine, 16 degrees for a "hot" engine. Below 100KPA add 0.3 degrees per 1 KPA drop. For boosted engines you subtract 0.3 degree for every 1 KPA above 100."

This is a good baseline tune, you of course have to tweak these numbers for you particular engine, modifications and environment"

Follwing this this is what I come up with for a 15psi boosted m20 (rough map)

|

Very interesting information- I've gone over your "rules" with a few engine specs- that were properly optimised on the Engine dyno and it seems to give a good starting point.

Where did you find that info?

Despite being an "old design" I would definately count the M20 2 valver hemi as a "modern" engine though. Short of twin plug I can't imagine a modern day manufacturer coming up with much better a compromise of airflow/power and good combustion. To your "rules" you could minus about 5 to 6 degrees maximum ignition advance if the engine is a twin plug hemi- I've seen this on Porsche 911 data, Aprilia Motor cycles and Alfas.. |

|

|

| redmist |

Posted

Thursday, Feb 15th 7:29pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 1030

NY USA

357i , 325i e30 turbo |

Marquis it was extracted from some Megasquirt II supporting documents.

I also learned, probably obvious to you, that the objective is torque optimization without detonation. So for those of us lucky enough to have unlimited use of a dyno (I am not one of those) the fine tuning would be to start with a base line and hold a steady state load on the dyno and change the advance in each rpm cell to give the maximum torque value without detonation.

For us of more modest means it's the old knock sensor, wide band oxygen senor and SOP trial and error. Adjusting injector pulse width and VE table to achieve target AFRs while tweaking the advance. |

|

|

| imaradiostar |

Posted

Thursday, Feb 15th 10:40pm [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 1011

Nashville, TN

81 323i, 82 525i, 85 524td, 90 535i |

So the 885 head is about as good as it gets short of a Porsche twin plug head?

Why do you suppose people seem to struggle to get extreme power levels out of m20 engines without forced induction? What is holding it back?

jamie |

|

|

| Marquis_Rex |

Posted

Friday, Feb 16th 8:49am [Edit] [Quote] [IMS] [View car] |

Member

Post nr. 521

UK

BMW 323i 2.7-as featured in Total BMW Nov 2002,Porsche 911/993TT |

| imaradiostar wrote: | So the 885 head is about as good as it gets short of a Porsche twin plug head?

Why do you suppose people seem to struggle to get extreme power levels out of m20 engines without forced induction? What is holding it back?

jamie |

A variety of reasons, when the capacities rocket- the valves are relatively quite small compared to the cylinder size- if you fit 45 mm valves- then your valve lift is limited at TDC as intake and exhaust valves can hit- unlike the M30 and at some point the small plenum crab like inlet manifold becomes a restriction also.

That said- I think 80 Bhp/litre is possible quite easily with the smaller capacity M20 (2.3 and 2.5). |

|

|